Perforated plate#

Highlights

This tutorial explores the following topics:

Mesh of a perforated plate with elliptical holes using Zmaster GUI, or using an ad-hoc mesher.

Compute stress and strain values expressed in cylindrical coordinate systems.

Compute the gradient of stress/strain along a line set.

Problem specification#

In this tutorial, we will explore the problem of a plate with an elliptic hole subjected to uniform tensile stress. The finite element results will be compared to analytical solutions where available. First, we will start with a circular hole subjected to a uniform uni-axial tensile stress. Then we will discuss the effect of larger holes compared to the plate dimensions. Finally, we will consider elliptic holes.

Analytical solutions#

Plate with a circular hole subjected to a uniform uni-axial tensile stress:

The stress field solution as found by Kirsch [T2] in cylindrical coordinates is given by

\[\begin{split}\begin{aligned} \sigma_{rr}(r,\theta)&=\dfrac{\sigma_\infty}{2}\left(1-\dfrac{a^2}{r^2}\right)+\dfrac{\sigma_\infty}{2}\left(1+\dfrac{3a^4}{r^4}-\dfrac{4a^2}{r^2}\right)\cos{(2\theta)}\\ \sigma_{\theta\theta}(r,\theta)&=\dfrac{\sigma_\infty}{2}\left(1+\dfrac{a^2}{r^2}\right)-\dfrac{\sigma_\infty}{2}\left(1+\dfrac{3a^4}{r^4}\right)\cos{(2\theta)}\\ \sigma_{r\theta}(r,\theta)&=-\dfrac{\sigma_\infty}{2}\left(1-\dfrac{3a^4}{r^4}+\dfrac{2a^2}{r^2}\right)\sin{(2\theta)} \end{aligned}\end{split}\]

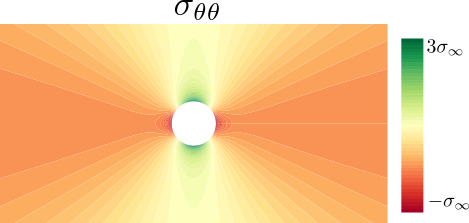

The \(\sigma_{\theta\theta}\) stress is positive for \(\pi/3<\theta<2\pi/3\) and \(-2\pi/3<\theta<-\pi/3\), and negative elsewhere. The stress \(\sigma_{\theta\theta}\) for \(\theta=\pi/2\) is denoted by \(\sigma_y\)

\[\sigma_y = \sigma_\infty\left(1+\dfrac{1}{2}\dfrac{a^2}{x^2}+\dfrac{3}{2}\dfrac{a^4}{x^4}\right)\]The gradient of stress \(\sigma_y\) along the hole axis

\[\dfrac{d\sigma_y}{dx}= -\sigma_\infty a^2\left(\dfrac{1}{x^3}+\dfrac{6a^2}{x^5}\right), \qquad \dfrac{d\sigma_y}{dx}\biggl|_{x=a}= -7\dfrac{\sigma_\infty}{a}\]At the edge of the hole with r = a,

\[\sigma_{rr}=\sigma_\infty(1-2\cos{(2\theta)})\]The maximum stress around the circle is located at \(\theta = \pi/2\) or \(\theta = 3\pi/2\)

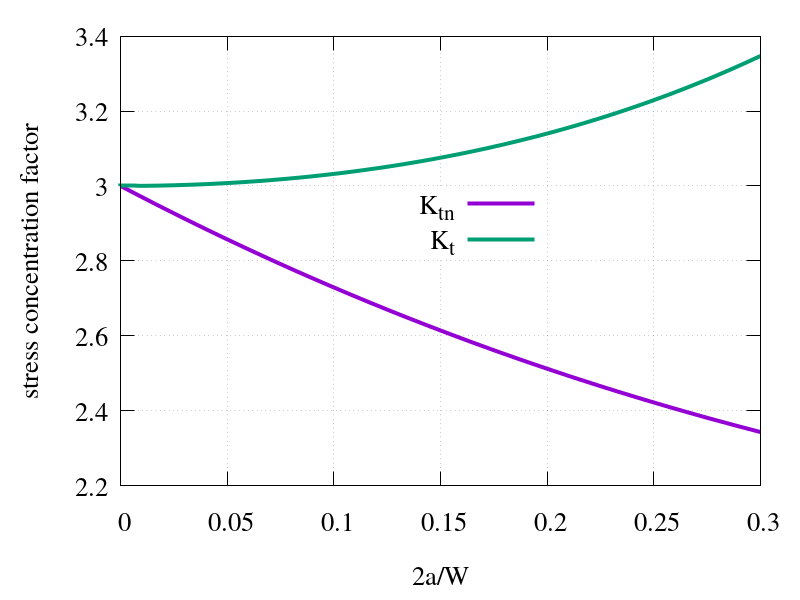

The stress concentration factor, \(K_t\), is the ratio of maximum stress at the hole to the remote stress:

\[K_t = \dfrac{\sigma_{max}}{\sigma_\infty}=\dfrac{\sigma_{\theta\theta}(a,\pm \pi/2)}{\sigma_\infty}=3\]Note that for an infinite plate, the stress concentration factor is independent of the hole size.

Finite Width Effects: for finite width plates, we introduce a nominal stress defined by

\[\sigma_{nominal}=\dfrac{W}{W-2a}\sigma\]For this case, the stress concentration factor will be defined as \(K_{tn}=\dfrac{\sigma_{max}}{\sigma_{nominal}}\). An empirical formula for \(K_{tn}\) is

\[K_{tn} = 3 - 3.14 \left( {2a \over W} \right) + 3.667 \left( {2a \over W} \right)^2 - 1.527 \left( {2a \over W} \right)^3\]The stress concentration factor \(K_{tn}\) varies between 2 (\({2a\over{W}} \longrightarrow 1\) ) and 3 (\({2a\over W} \longrightarrow 0\)).

Elliptic holes:

The maximum \(\sigma_{\theta\theta}\) stress is given by

\[\sigma_{\theta\theta}^{max}=\sigma_\infty \left(1+2\dfrac{a}{b}\right)\]The stress intensity factor is given by \(K_t=1+2\dfrac{a}{b}\). The gradient of stress along the y-axis

\[\dfrac{d\sigma_y}{dx}\biggl|_{x=a}= -\sigma_\infty \dfrac{a}{b^3}\left(4a+3b\right)\]

Mesh generation#

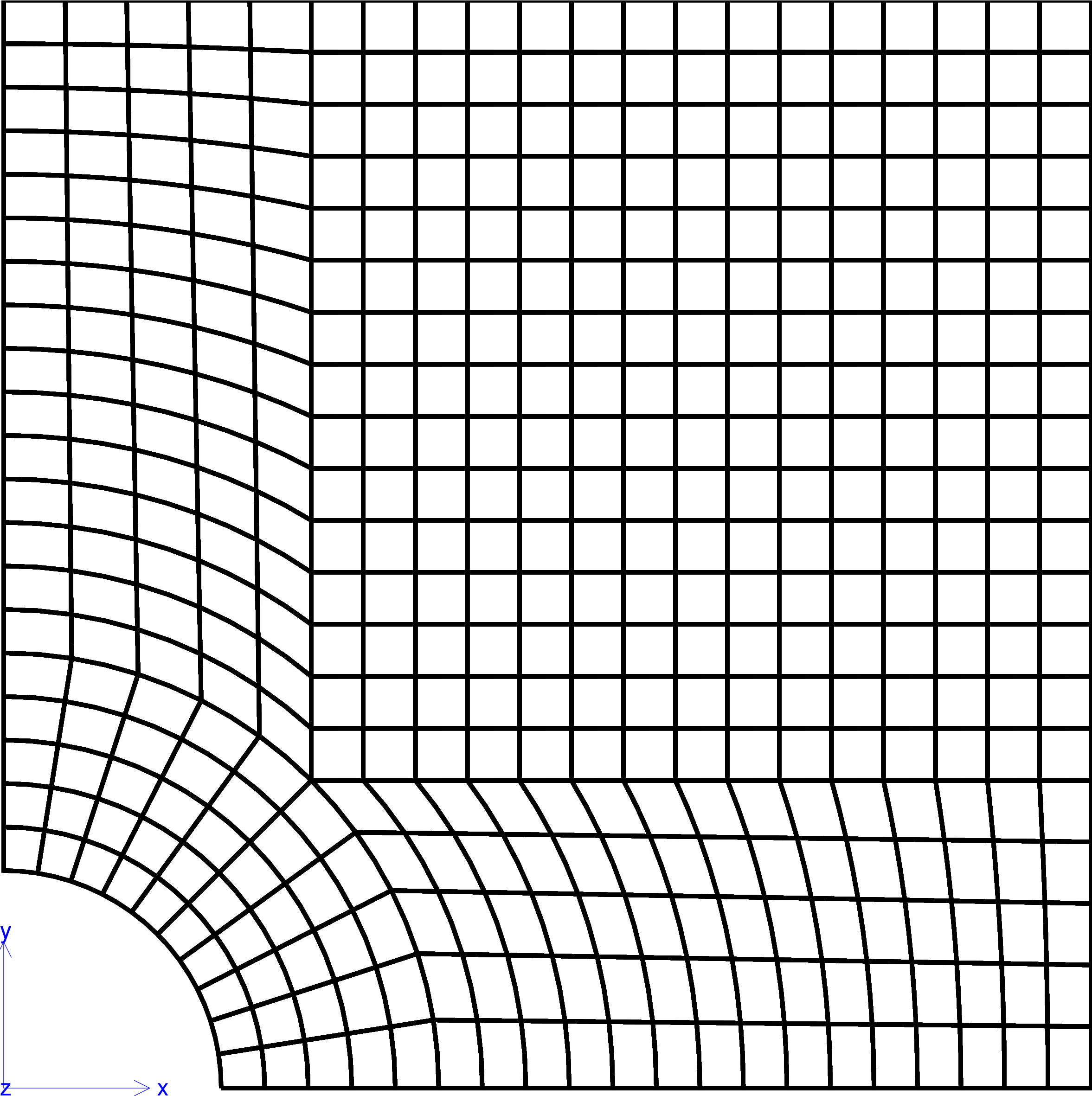

Fig. 43 The geometry of one-quarter of a plate with a hole.#

To create the mesh, two methods are used. The first one uses the Zmaster GUI to create the mesh, while the second one is based on a specific “mesher” developed to generate this kind of meshes. The second way is useful to create the mesh for elliptic hole which is not possible using the Zmaster interface.

Method 1#

To create the mesh of a quarter of a plate with elliptical hole using the Zmaster interface. For a plate having an edge length of 2 mm and circular hole of radius 0.2,

-

#Points X Y Z point0 0.0 0.0 0.0 point1 0.2 0.0 0.0 point2 0.4 0.0 0.0 point3 1. 0.0 0.0 point4 1. 0.282842712 0.0 point5 1. 1. 0.0 point6 0.282842712 1. 0.0 point7 0.0 1. 0.0 point8 0.0 0.4 0.0 point9 0.0 0.2 0.0 point10 0.282842712 0.282842712 0.0 point11 0.141421356 0.141421356 0.0

-

#Lines 1st point -- 2nd point line0 point1 -- point2 line1 point2 -- point3 line2 point3 -- point4 line3 point4 -- point5 line4 point5 -- point6 line5 point6 -- point7 line6 point7 -- point8 line7 point8 -- point9 line8 point4 -- point10 line9 point10 -- point6 line10 point11 -- point10

#Arcs 1st point 2nd point center radius theta1 theta2 arc0 point1 point11 point0 0.2 0.0 0.785398 arc1 point11 point9 point0 0.2 0.785398 1.570796 arc2 point2 point10 point0 0.4 0.0 0.785398 arc3 point10 point8 point0 0.4 0.785398 1.570796

-

#domain element types boundary Ruled0 c2d8r arc0 line10 arc2 line0 Ruled1 c2d8r arc1 line7 arc3 line10 Ruled2 c2d8r arc2 line8 line2 line1 Ruled3 c2d8r line8 line9 line4 line3 Ruled4 c2d8r arc3 line6 line5 line9

Specify the number of nodes at each edge

(the number of nodes at opposite sides

should be the same)

(the number of nodes at opposite sides

should be the same)-

#Bsets Boundary x0 line7 -- line6 x1 line2 -- line3 y0 line0 -- line1 y1 line5 -- line4 hole_egde arc0 -- arc1

Method 2#

Alternatively, the mesh can be created using the **mesh_quarter_plate_hole mesher, which

enables the creation of a mesh based on multiple parameters ( plate edge length, hole radius, …)

as shown below:

% file mesh_plate.inp

****mesher

***mesh plate_circular_hole.geof

**mesh_quarter_plate_hole

*ncut_radius 20 % number of elements in radial-direction

*ncut_theta 30 % number of elements in theta-direction

*size_square 1.00 % plate edge length / 2

*size_hole 0.2 % radius a

*nb_reg 3 % number of mesh layers with the same hole roundness

*quad % quadratic mesh

*geometrical_progression 1.1 % mesh progression in radial direction,

% finer mesh near the hole

*hole_anisotropy 1. % aspect ratio b/a , 1 = hole is circular

*balance_nodes

% the following bset are required for calcul and post-processing

**bset x0 *use_nset x0

**bset y0 *use_nset y0

**bset x1 *use_nset x1

**bset y1 *use_nset y1

**rename_set *nsets layer_0 hole_edge

**bset hole_edge *use_nset hole_edge

**set_reduced % reduced integration

****return

To run this mesher, open a terminal and execute

> Zrun -m mesh_plate.inp

This will create plate_circular_hole.geof mesh file, which can be visualized using the command

> Zmaster plate_circular_hole.geof

Finite element analysis#

The input file to perform a finite element computation

Finite element formulation#

****calcul mechanical

***mesh plane_stress

**file plate_circular_hole_4.geof

Global problem resolution#

***resolution

**sequence

*time 1.

*increment 1

Boundary conditions#

The following boundary conditions are applied:

For symmetry, the displacement of

x0along x-direction andy0along y-direction is set to 0.Apply a tensile loading using

**pressureon the bsetx1, with \(P^{\tt x1}(t)=100t\).

***bc

**impose_nodal_dof

x0 U1 0.0

y0 U2 0.0

**pressure x1 100. time

Material behavior#

The material behavior file and the integration method (required for plastic models) are specified as

***material

*file elastoplastic.mat % or elastic.mat

*integration theta_method_a 1. 1e-12 100 % this is not required for an elastic model

Elastic material behavior

% elastic.mat file ***behavior gen_evp **elasticity isotropic young 200000. poisson 0.3 ***return

Elastoplastic material behavior

% elastoplastic.mat file ***behavior gen_evp **elasticity isotropic young 200000. poisson 0.3 **potential gen_evp ep *flow plasticity *criterion mises *isotropic constant R0 300. ***return

Output results#

The value of stress components \(\sigma_{11}\), \(\sigma_{22}\) and \(\sigma_{12}\) along

the boundary lines x0, y0 and hole_edge can be output in ASCII files (one file for each

liset as):

***output

**curve stress_x0.test

*liset_var x0 X Y sig11 sig22 sig12

**curve stress_y0.test

*liset_var y0 X Y sig11 sig22 sig12

**curve stress_edge.test

*liset_var hole_edge X Y sig11 sig22 sig12

Note that the stress values are extrapolated to line set (liset) nodes.

Post-processing#

The following input file allows to apply a series of post-processing steps:

**process transform_frame: compute stress tensor components in the cylindrical coordinate system. It will create variables namedsig11-rot, …,sig12-rot.**process node_extrapolation: extrapolate the values of stress in cylindrical coordinates to nodes. Here we extrapolate onlysig11-rotandsig22-rot(the output names for the newly created nodal variables are chosen to besig_rr,sig_tt, respectively).**process gradient: compute the gradient of a stress component (e.g. \(\dfrac{\partial \sigma_{\theta\theta}}{\partial Y}\)). The name of this variable isgradYsig_tt.**process node_extrapolation: extrapolate the value of the stress gradient to nodes. The name of the corresponding nodal variable is chosen asNgradYsig_tt.**process format: export the specified variables at specified maps to an output ASCII file.

****post_processing

***global_post_processing

% **output_number 1

%-------------------------------------

**file integ

**elset ALL_ELEMENT

**process transform_frame

*local_frame cylindrical

(0. 0. 0.) (0. 0. 1.)

*tensor_variables sig

%-------------------------------------

**process node_extrapolation

*list_var sig11-rot sig22-rot % the name of the field to be extrapolated

*output_var sig_rr sig_tt % the output name

%-------------------------------------

**file node

**nset ALL_NODE

**process gradient Y *var sig_tt % this will compute gradYsig_tt = d{sig_tt}/dY

%-------------------------------------

**file integ

**elset ALL_ELEMENT

**process node_extrapolation

*list_var gradYsig_tt

*output_var NgradYsig_tt

%-------------------------------------

**file node

**nset x0 % for example

**output_number 34 % map number

**process format

*file results.dat % output filename

*list_var sig_rr sig_tt NgradYsig_tt

*write_nodal_coordinates coord

****return

To run this post-processing, execute

Zrun -pp plate_tension1.inp

The variables computed by these post-processings are stored in the plate_tension1.integp/plate_tension1.nodep files.

Results & discussion#

In this section, finite element solutions will be compared to analytical solution for isotropic elasticity and for elasto-plasticity. The case of uni-axial and bi-axial tensile loading is addressed.

Isotropic elasticity#

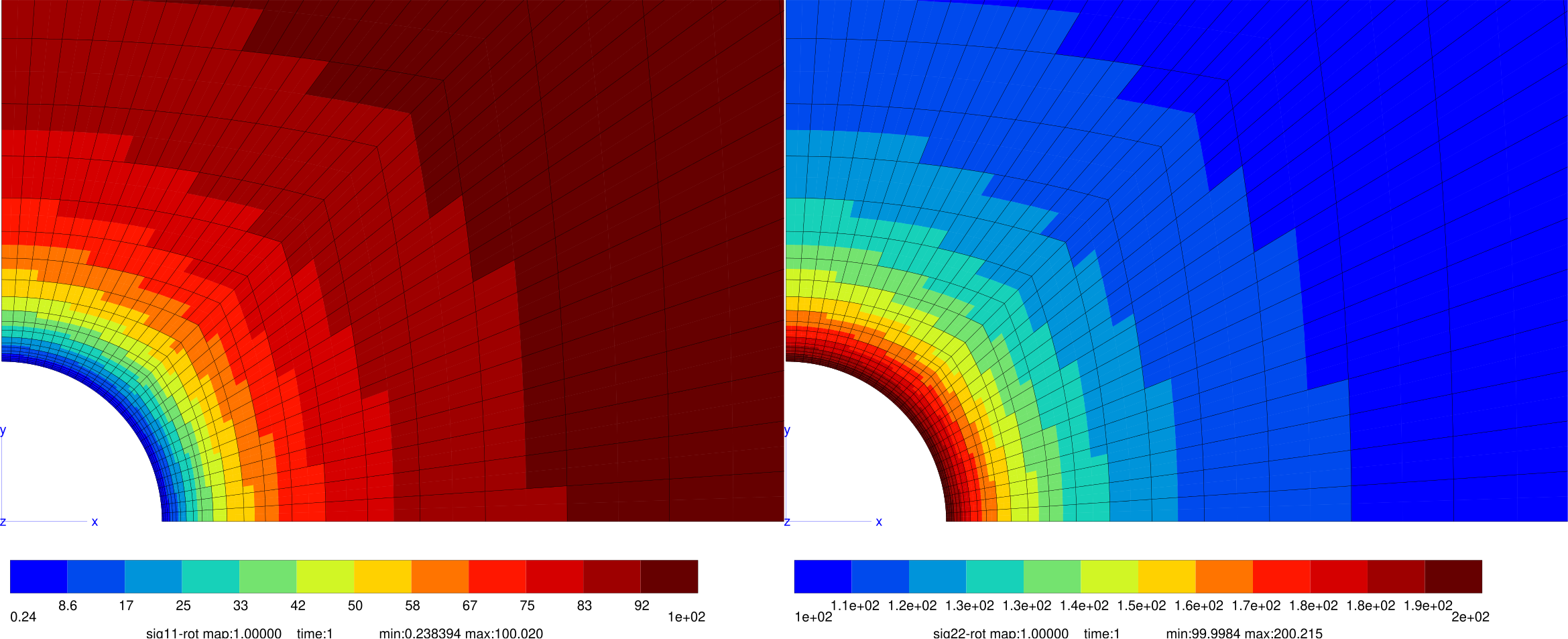

Uni-axial tensile loading (circular hole)

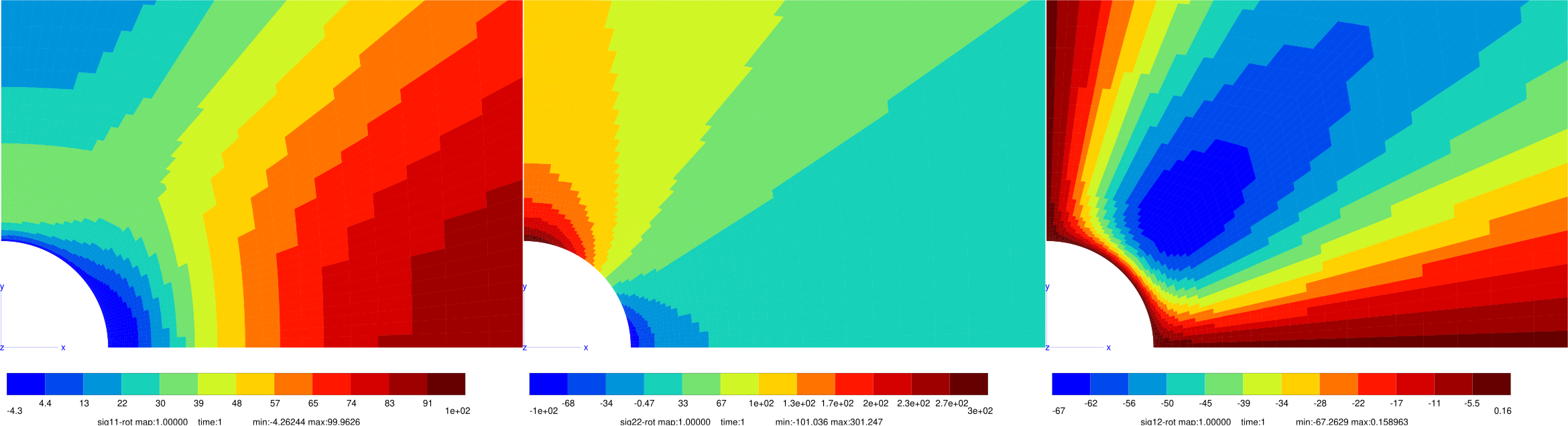

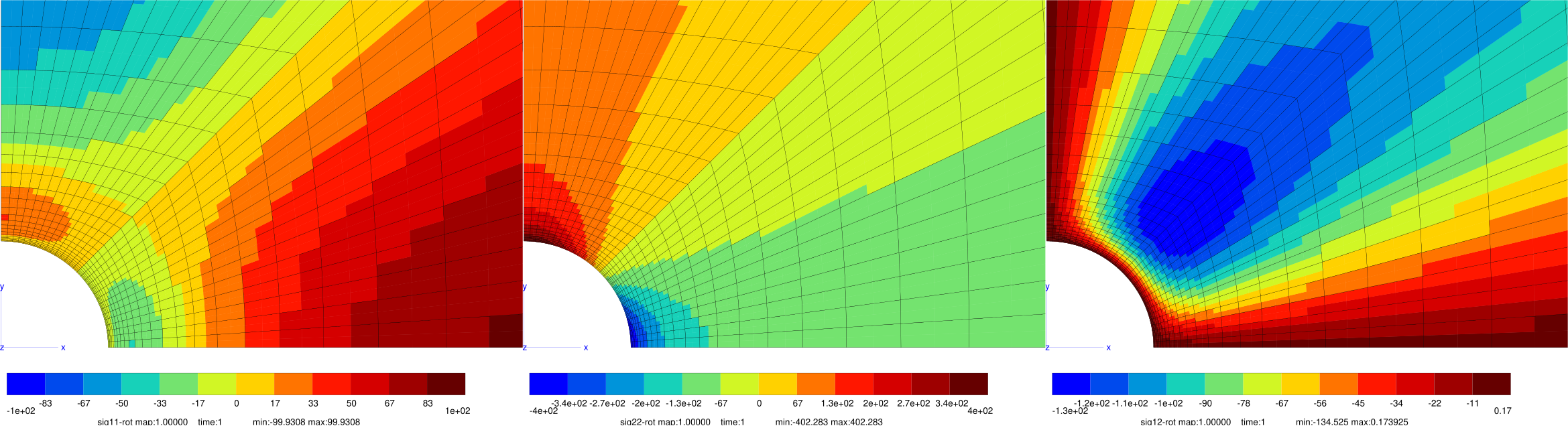

Fig. 44 Finite element solution for \(\sigma_{rr}\) (left), \(\sigma_{\theta\theta}\) (middle), and \(\sigma_{r\theta}\) (right).#

Bi-axial tensile loading (circular hole)

For infinite plate with a circular hole, the solution can be derived by superposing the solutions of uni-axial tensile loading obtained for \(\theta\) and \(\theta+\pi/2\).

We denote by \(\alpha = \dfrac{\sigma_\infty^2}{\sigma_\infty^1}\). The stress concentration factors at points A and B are given by:

\[K_t^A=3\alpha-1, \qquad ~K_t^B=3-\alpha\]When \(\sigma_\infty^1\) and \(\sigma_\infty^2\) have the same magnitude but are of opposite sign (pure shear \(\alpha=-1\)), \(K_t^A=-4, \text{and}~K_t^B=4\).

To apply a bi-axial stress, one can modify the input file as

***bc **impose_nodal_dof x0 U1 0.0 y0 U2 0.0 **pressure x1 100. time y1 100. time % for alpha = 1

Fig. 45 Finite element solution for \(\alpha=1\): \(\sigma_{rr}\) (left) and \(\sigma_{\theta\theta}\) (right). The stress \(\sigma_{r\theta}\approx 0\).#

Fig. 46 Finite element solution for \(\alpha=-1\): \(\sigma_{rr}\) (left), \(\sigma_{\theta\theta}\) (middle), and \(\sigma_{r\theta}\) (right).#

The finite element results agree perfectly with the analytical solution.

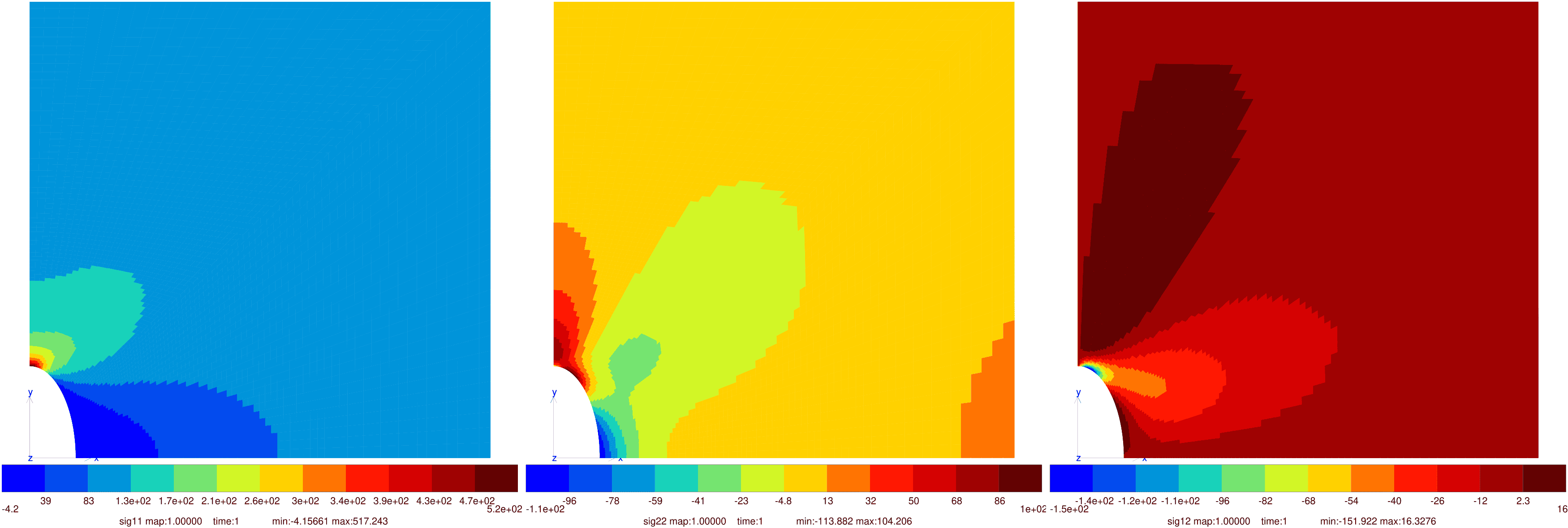

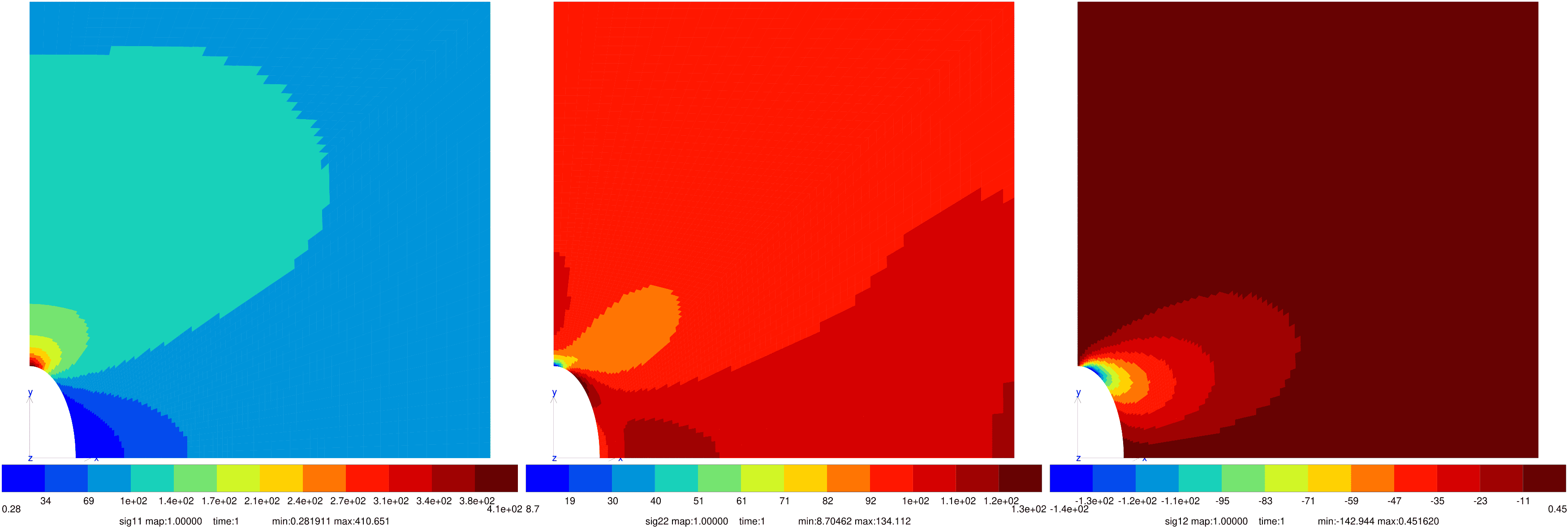

Elliptical hole

For a infinite plate with an elliptic hole subjected to uni-axial loading, the stress concentration factor is of \(K_t=1+{2a \over b}\). For biaxial loading (\(\alpha=1\)), \(K_t ={2a \over b}\). Finite element results are slightly different because the plate has a finite width.

Fig. 47 Finite element solution for a plate with an elliptic hole subjected to uni-axial loading.#

Fig. 48 Finite element solution for a plate with an elliptic hole subjected to bi-axial loading.#

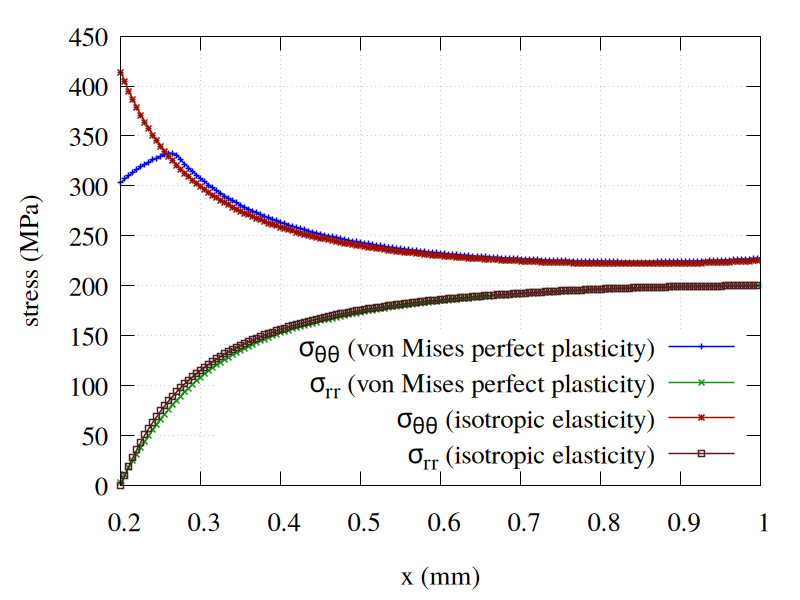

Elasto-plasticity#

Now, we assume that the material is elasto-plastic, and consider a biaxial loading (\(\alpha=1\)) with \(\sigma_\infty = 200 MPa\).

Fig. 49 Comparison of finite element results (\(\sigma_{rr}\) and \(\sigma_{\theta\theta}\)) for an isotropic elastic model and a perfect von Mises plasticity model (\(R_0 = 300\) MPa).#

Downloads

Mesh files

Input files