A elastoplastic analysis of a disk under rotation#

Highlights

This tutorial explores the following topics:

Mesh a simple geometry.

Apply a centrifugal force.

Estimate the limit rotational speeds of bored disks.

Compare results of a ‘thin’ and a ‘thick’ disk.

Problem specification#

Rotating machines are common in industrial structures. Discs and shafts are critical parts in, for example, aircraft engines and turbines for power generation. They are subject to high centrifugal forces and must not fail. Therefore, their design is crucial for the integrity of the structure in service.

The objective of this tutorial is to estimate the limit rotational speeds of bored disks. We assume that material model of the disk is perfectly elasto-plastic. In this problem, we consider isothermal conditions under small perturbations. The rotational speed of the disk burst can be estimated by the speed that leads to the propagation of plasticity throughout the disk.

Two cases are considered: the case of a thin disk and the case of a thick disk. In the first case, plane stress conditions are applied. The analytical solutions are detailed in [T3, T4]. In the second case, this hypothesis is not satisfied anymore. Some finite element results for that case are provided. In the rotating frame of reference attached to the disk, the equilibrium equations are given by

where \(\rho\) is the material density and \(\rho \vect{f} = \rho \omega^2 r \vect{e}_r\) is the volume forces induced by the angular velocity \(\omega\).

Analytical solutions#

The analytical solution of a simplified version of this problem is given in [T4] for an axisymmetric thin disk under plane stress conditions. In the latter reference, solutions are given for a Tresca plasticity criterion. The analytical solution for von Mises is inextricable since the stress components \(\sigma_{rr}\) and \(\sigma_{\theta\theta}\) are coupled.

Summary of analytical solutions for Tresca plasticity model:

Radial stress \(\sigma_{rr}\)

where a is the location of the elastic-plastic boundary. It can be computed by solving \(\sigma_{\theta\theta}(r=a)=\sigma_0\).

Tangential stress \(\sigma_{\theta \theta}\)

Radial strain \(\varepsilon_{rr}\)

Tangential strain \(\varepsilon_{\theta \theta}\)

Radial displacement \(u_r\)

where \(A\), \(B\) and \(C\) are integration constants given by

Mesh generation#

Fig. 50 A schematic representation of a bored turbine disk. The cylindrical coordinates are adopted. For 2D case, simulations are considered in the x-y plane which means that the rotation axis is parallel to \(\vect{e}_y\).#

-

for a thin disk:

#Points x y z point0 5. 0. 0. point1 50. 0. 0. point2 50. 0.1 0. point3 5. 0.1 0.

for a thick disk:

#Points x y z point0 5. 0. 0. point1 50. 0. 0. point2 50. 10. 0. point3 5. 10. 0.

-

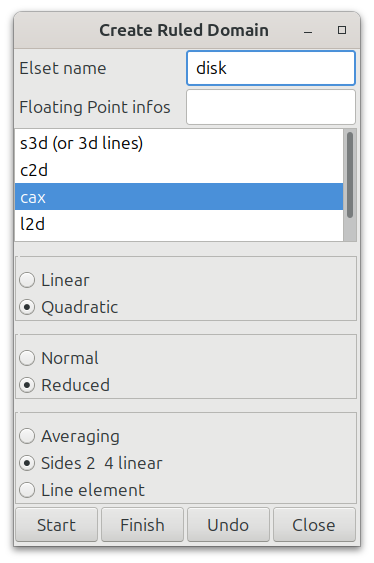

Fig. 51 The disk is meshed using axisymmetric elements

cax8r(quadratic elements with reduced integration).# Create boundary sets

(see Fig. 52)

(see Fig. 52)

Fig. 52 The mesh of a thick disk and the boundary sets  .#

.#

The user can also download the geometry file disk_thin.mast.

Open the file with Zmaster and mesh the domain by clicking on  \(\longrightarrow\)

\(\longrightarrow\)  (or run the command

(or run the command Zrun -B thin_disk.mast). The position of points in the .mast file can be

modified to change the disk dimensions.

Finite element analysis#

Finite element formulation#

A small strain axi-symmetric model is used for this simulation.

****calcul

***mesh % by default 3D small_deformation

**file disk_thin.geof

Global problem resolution#

To solve the global problem, a Newton-Raphson algorithm is used.

One loading sequence from time = 0 to time = 1: the number of increments is set to 20, with a maximum number of iterations of 10. The relative convergence ratio is \(0.1\%\). The tangent matrix will be updated at each iteration (

*algorithm p1p2p3).Automatic time-stepping: the first increment \(\Delta t\) is 0.01. If the algorithm converge, the time-step will be multiplied by \(1.2\) (

*security) and if it diverges the time-step will be divided by 2 with a maximum number of divergence 10. The optionglobal 6is used to subdivide time-step for the subsequent increment if the number of iterations per increment exceeds 6.

***resolution % by default newton

**sequence 1

*time 1.

*increment 20

*iteration 10

*ratio 0.1

*algorithm p1p2p3

**automatic_time global 6

*security 1.2

*divergence 2. 10

*first_dtime 0.01

Boundary conditions#

We consider a symmetric disk w.r.t to the plane defined by \(z=0\) (or \(y=0\)

in the simulation) which corresponds to the boundary set bottom. The displacement of the inner part

of the disk (hub) in the radial direction is set to zero. The disk rotates at a constant angular velocity \(\omega \vect{e}_z\).

***bc

**impose_nodal_dof

bottom U2 0.

hub U1 0.

**centrifugal

ALL_ELEMENT (0.0 0.0) d2 10000. time % omega = 10000 rad/s

Material behavior#

We consider a perfect elastoplastic material model with Young modulus \(E=205000\) MPa and a Poisson’s ratio of \(\nu=0.3\). Two plasticity criteria are adopted: von Mises and Tresca.

% elastoplastic.mat

***behavior gen_evp

**elasticity isotropic

young 205000.

poisson 0.3

**potential gen_evp ep

*criterion tresca % or mises

*isotropic constant

R0 1000.

***coefficient

masvol 8.08e-9

***return

Note

In Z-set, the implemented version of the Tresca model is slightly different than the standard version found in literature since the normal to the yield surface of Tresca model at the corners is chosen as the average of intersecting surfaces normals. Alternatively, one can consider the Hosford model given by

where \(\sigma_I\), \(\sigma_{II}\), and \(\sigma_{III}\) are principal stresses. The Hosford model becomes equivalent to Tresca one by choosing higher values of the parameter \(a\).

To integrate constitutive equations, an implicit generalized midpoint integration method (theta_method_a) is used, with \(\theta=1\), a tolerance of \(10^{-12}\), and the maximum number of iterations is set to \(100\).

***material

*file elastoplastic.mat

*integration theta_method_a 1. 1e-12 100

Results & discussion#

Thin disk#

Comparison between Tresca and von Mises plasticity criteria

Fig. 53 Analytical (lines) and numerical (marked points) solutions for a Tresca perfect plasticity model. \(r_i=5 mm\) and \(r_e=50 mm\) (thickness \(H=1 mm\))#

Fig. 54 Finite element solution for a von Mises perfect plasticity model. \(r_i=5 mm\) and \(r_e=50 mm\) (thickness \(H=1 mm\))#

Thick disk#

Consider a thick disk, with its thickness H being significant in comparison to its external radius \(r_e\) (\(H/r_e=0.2\)). The finite element solutions are provided for both Tresca and von Mises perfect plasticity models. When the disk is not “thin” anymore, the stress components \(\sigma_{zz}\) and \(\sigma_{rz}\) do not vanish. Moreover, the fields of \(\sigma_{zz}\) and \(\sigma_{rz}\) are dependent on the z-coordinate. The stress components \(\sigma_{rr}\) and \(\sigma_{\theta\theta}\) exhibit a slight variation along \(z\) (or \(y\) in figures above), which will become more pronounced when the thickness of the disk is increased.

Fig. 55 Stress fields \(\sigma_{rr}\), \(\sigma_{\theta\theta}\), \(\sigma_{zz}\), and \(\sigma_{rz}\) obtained by the finite element method for a thick disk. Results are obtained for a Tresca perfect plasticity model. Displacements have been exaggerated for illustration purposes (\(\times 100\)). The initial state of the disk is shown in red.#

Fig. 56 Stress fields \(\sigma_{rr}\), \(\sigma_{\theta\theta}\), \(\sigma_{zz}\), and \(\sigma_{rz}\) obtained by the finite element method for a thick disk. Results are obtained for a von Mises perfect plasticity model.#

Downloads

Mesh files

Input files

Miscellaneous