Contact between two curved beams#

Highlights

The main objectives of this tutorial are:

To demonstrate how to create a mesh using Zmaster (definition of points, lines, and curves, creation of domains, and the definition of several boundary sets useful for applying boundary conditions).

To create an input file to carry out a large deformations elasto-plastic computation in plane strain conditions. The definition of contact between the two beams is handled for cases with and without friction.

To illustrate how to obtain reaction force values on a set of nodes.

Problem specification#

We consider two contacting curved beams. This problem was introduced by [T5] using a mortar method, and re-addressed by [T6]. One beam is fixed and another is given a horizontal displacement \(d = 32 mm\). Both beams are modelled using a large deformation isotropic hardening elasto-plastic material. The isotropic elasticity properties are given by \(E=689.56\) MPa, and \(\nu=0.32\). The yield stress is \(\sigma_y=31\) MPa, and the plastic modulus is \(H = 261.2\) MPa.

Fig. 68 The geometry of two curved beams. A displacement \(u_x\) is applied on the top of the upper beam. The lower beam is fixed at the bottom.#

Mesh generation#

To create the mesh using the Zmaster GUI:

Open Zmaster Interface

Create points

\(\longrightarrow\)

\(\longrightarrow\)

#Points x y z point0 0.0 0.0 0.0 point1 10.0 0.0 0.0 point2 12.0 0.0 0.0 point3 -12.0 0.0 0.0 point4 -10.0 0.0 0.0 point5 -15.0 17.0 0.0 point6 -25.0 17.0 0.0 point7 -23.0 17.0 0.0 point8 -5.0 17.0 0.0 point9 -7.0 17.0 0.0

-

Select Arc: center, pt1, pt2 \(\longrightarrow\) Go

Create arcs (in any order). Ensure that the points are selected in an anticlockwise order.

#Arcs center pt1 pt2 arc0 Point0 point2 point3 arc1 Point0 point1 point4 arc2 Point5 point6 point8 arc3 Point5 point7 point9

Click on Close.

-

Select 2 Points \(\longrightarrow\) Go

Create the following lines (in any order):

#Lines pt1 pt2 line0 point7 point6 line1 point8 point9 line2 point3 point4 line3 point1 point2

Define the number of nodes at each edge

Specify the number of nodes on lines in Num field, e.g. 2 (let Progression=1) \(\longrightarrow\) Go.

Click on the four lines lines.

Specify the number of nodes on arcs, e.g. Num = 20 \(\longrightarrow\) Go.

Click on the four arcs.

Click on Close

-

Specify the Elset name.

Select c2d element type, quadratic, Reduced, and Sides 2 4 linear \(\longrightarrow\) Start.

After selecting the bounding edges of each domain, click on Finish.

#Domains b1 b2 b3 b4 lower_beam arc1 line2 arc0 line3 upper_beam arc3 line1 arc2 line0

Ensure that the 2nd and 4th selected edges are lines.

Click on Close.

-

Specify Name, select Quadratic, and click on Start.

Select a boundary set, and click on Finish (after each boundary set)

#Bsets boundaries lower_bot line2 line3 upper_top line1 line0 lower_ext arc0 upper_ext arc2

Click on Close.

Save the project

.mastand the.geoffile. (File \(\longrightarrow\) Save)

Finite element analysis#

Finite element formulation#

An updated Lagrangian formulation is used, with plane strain conditions

***mesh updated_lagrangian_plane_strain

**file curved_beams.geof

Global problem resolution#

One loading sequence (

time= 0 to 1) is applied.A Newton-Raphson algorithm is used, where the tangent matrix is always updated during iterations (

p1p2p3).The number of increments is set to 100, with maximum iterations per increment of 20.

Set automatic time-stepping

**automatic_time:*divergence 3. 10: to divide time increment by 2 (10 subsequent divergences are allowed).*security 1.2: when convergence is retrieved, multiply time increment by1.2.*first_dtime 1e-3: apply a first time increment of1e-3for the sequence.

***resolution

**sequence 1

*time 1.

*increment 100

*iteration 20

*ratio automatic 0.1

*algorithm p1p2p3

**automatic_time epcum 0.1

*security 1.2

*divergence 3. 10

*first_dtime 1e-3

Boundary conditions#

Fix

lower_botnode set: the displacementU1andU2is set to 0.Set vertical displacement

U2ofupper_topnode set to 0.Apply a horizontal displacement on

upper_topas a function of time: \(U_1^{\tt upper\_top}(t)=32t\).

***bc

**impose_nodal_dof

lower_bot U1 0.

lower_bot U2 0.

upper_top U2 0.

upper_top U1 32. time

Contact definition#

A mortar contact will be used in this case based on an Augmented Lagrangian method.

Frictionless case:

***mortar_contact **interface alm_contact *nmortar_side lower_ext *mortar_side upper_ext *warning_dist 2.

Frictional case:

***mortar_contact **interface alm_fric_contact *nmortar_side lower_ext *mortar_side upper_ext *warning_dist 2. *fric_coeff 0.3

Material behavior#

Consider an elastoplastic gen_evp model with:

isotropic elasticity,

von Mises plasticity with linear isotropic hardening.

The keyword lagrange_rotate is a modifier that extends the model to finite strain

(corotational formulation based on Jaumann-derivative). The material input file is given as

***behavior gen_evp lagrange_rotate

**elasticity isotropic

young 689.5

poisson 0.32

**potential gen_evp ep

*isotropic linear

R0 31. H 261.2

***return

A \(\theta\)-method is employed to integrate the constitutive equations, with \(\theta=1\). The convergence tolerance is set to \(10^{-12}\), and the maximum number of iterations allowed is 200.

***material

**elset ALL_ELEMENT

*this_file % if the material behavior is defined within the same input file

*integration theta_method_a 1. 1.e-12 200

Output results#

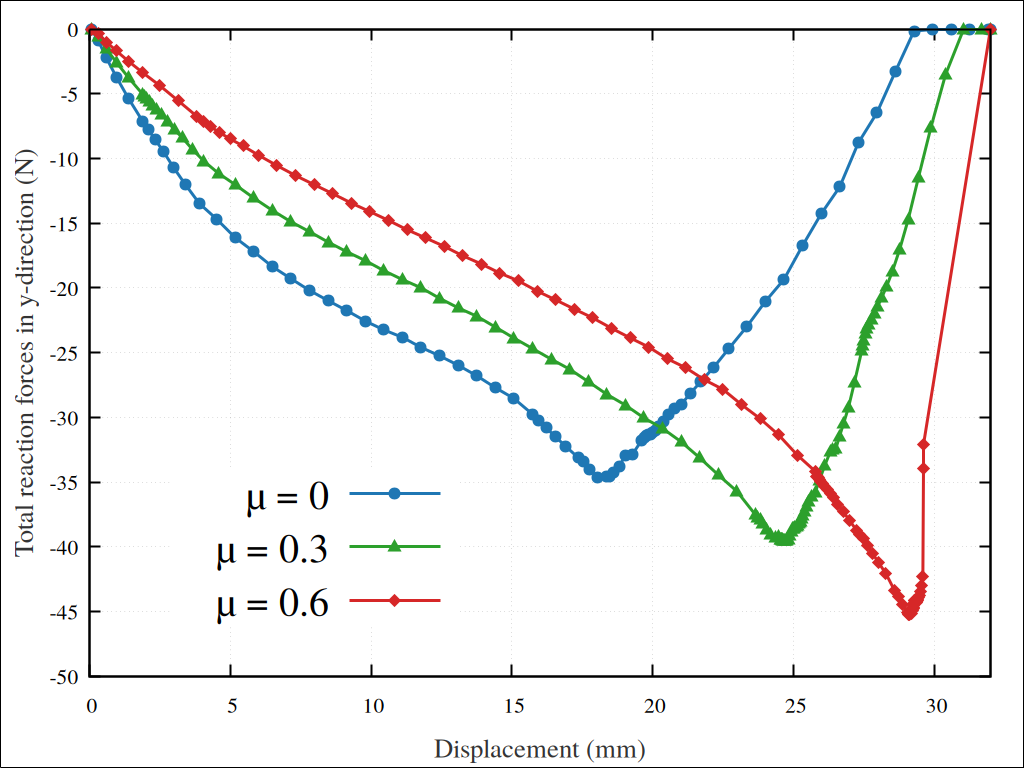

The reaction forces will be saved to an output file, e.g. Reaction_upper_0_3.dat.

This file will include three columns: time, RU1 and RU2.

***output

**curve Reaction_upper_0_3.dat

*nset_var upper_beam U1 U2

To run this computation, open a terminal and launch

Zrun contact_curved_beams

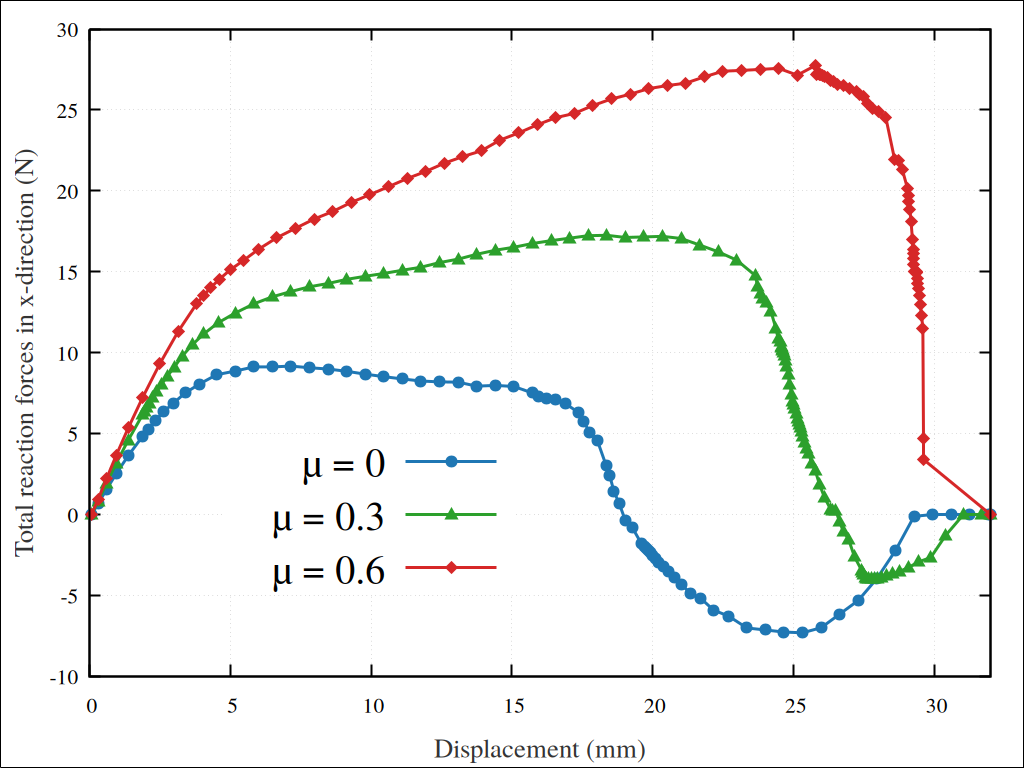

Results & discussion#

To visualize the results:

Open Zmaster

Zmaster contact_curved_beamsSelect nodal or integration points variables (e.g.

epcum) \(\longrightarrow\) Draw.To create an animation, click on Anim \(\longrightarrow\) Go (Adjust the number of maps as needed by specifying Steps)

Fig. 69 Cumulative plastic strain for \(\mu=0\) (maximum value 0.1201)#

Fig. 70 Cumulative plastic strain for \(\mu=0.3\) (maximum value 0.1543)#

Fig. 71 Cumulative plastic strain for \(\mu=0.6\) (maximum value 0.2044)#

To plot reaction forces stored in

Reaction_upper_0_3.datfile:click on Add/Del..

select datafile click on New, and specify the datafile name in file (

Reaction_upper_0_3.dat) \(\longrightarrow\) OK. Now a line is added below liset : … in the plot panel.Select the added line data file Reaction_upper_0_3.dat, and choose variables to plot \(\longrightarrow\) Draw

Fig. 75 Reaction force in the x-direction, for the upper beam, as function of its displacement for frictionless and frictional cases.#

Fig. 76 Reaction force in the y-direction, for the upper beam, as function of its displacement for frictionless and frictional cases.#

Downloads

Mesh files

Input files