Bending#

Highlights

Mesh a 2D/3D plate

Define boundary conditions to apply a bending.

Compute the bending moment using post-processing.

Problem specification#

Fig. 63 Schematic of a two-dimensional plate subjected to pure bending. For symmetry, only half of the plate will be used in the simulation.#

Analytical solution#

A foil with a length \(2L\) and width \(2w\) is subjected to pure bending under plane stress conditions and small strains. The applied curvature is denoted by \(\kappa\).

linear elasticity

Consider an isotropic elastic material with Young’s modulus \(E\) and Poisson’s ratio \(\nu\).

The stress tensor is given by \(\ten{\sigma}=\dfrac{E\kappa x_2}{I_3}\vect{e}_1\otimes\vect{e}_1=\dfrac{-M x_2}{I_3}\vect{e}_1\otimes\vect{e}_1\)

The strain tensor is given by \(\ten{\varepsilon}=\kappa x_2\left(\vect{e}_1\otimes\vect{e}_1-\nu(\vect{e}_2\otimes\vect{e}_2+\vect{e}_3\otimes\vect{e}_3)\right)\)

The displacement is given by \(\vect{u}=-\kappa x_1 x_2 \vect{e}_1+\dfrac{\kappa}{2}\left(x_1^2+\nu x_2^2\right)\vect{e}_2\).

where \(I_3=\dfrac{2w^3}{3}\) is the area moment of inertia, and \(M=-EI_3\kappa\) is the bending moment.

elasto-plasticity

The total strain is split in two parts: the elastic strain and the plastic strain

Consider a von Mises plasticity model. The yield criterion is given by \(f(\sigma,R)=J_2(\ten \sigma)-\sigma_0-R(p)\) where \(R(p)\) is the isotropic hardening function which depends on the cumulative plastic strain \(p\). At \(y=w\), the stress will reach the yield limit when \(|\sigma_{11}| = \sigma_0\), or when \(|\kappa| = \dfrac{\sigma_0}{E w}\). The width of the elastic zone near the neutral axis is \(2a\) where \(a=\dfrac{\sigma_0}{E|\kappa|}\).

The stress in the elastic/plastic regions is given by

For a linear isotropic hardening function \(R(p)=H p\), the cumulative plastic strain is given by

The bending moment is given by

The limit value of the bending moment will be:

Perfect plasticity (\(H=0\)): \(M_\infty=\sigma_0 w^2\)

Linear isotropic hardening: \(M_\infty=\dfrac{Ew^2}{E+H}\left(\sigma_0 +\dfrac{2H}{3}\kappa w\right) \xrightarrow{\kappa \to \infty} \infty\)

Mesh generation#

Note

To create the mesh, execute

> Zrun -B beam2D.mast

or open beam2D.mast with Zmaster

> Zmaster beam2D.mast

then click on  \(\longrightarrow\)

\(\longrightarrow\)  .

.

The following steps will guide you through creating the geometry files from scratch.

2D plate#

Open Zmaster GUI

-

#Points x y z point0 0.0 -0.5 0.0 point1 5.0 -0.5 0.0 point2 5.0 0.5 0.0 point3 0.0 0.5 0.0 point4 5.0 0. 0.0 point5 0.0 0. 0.0

The plate is rectangular and can be meshed using only 4 points. To increase node density near the neutral axis, the plate was subdivided into two rectangles.

-

Select 2 Points or Segments w/points \(\longrightarrow\) Go.

Create the following lines (in any order):

#Lines 1st point 2nd point line0 point1 point0 line1 point3 point3 line2 point3 point2 line3 point2 point4 line4 point4 point1 line5 point3 point5 line6 point5 point0 line7 point5 point4

Specify the number of nodes at each edge and the progression of nodes for non-uniform nodes’ distribution

.

.To refine the mesh at the middle of the plate (neutral axis), set the value of Progression \(>1\), and click near the line node where the mesh should be finer.

Note that the meaning of the progression value depends on the line definition. If the value of Progression is \(>1\), the spacing between nodes from the first to the last line point decreases; otherwise, it increases.

Define boundary sets on which boundary conditions will be applied later

left(resp.right) bsets : set Name and select quadratic \(\longrightarrow\) Start, then select the two lines with \(x=0\) (resp. \(x=5\)) in the drawing area \(\longrightarrow\) Finish.left_midbset: set Name and select Single Point \(\longrightarrow\) Start, then select the point 5 with \(x=y=0\) in the drawing area \(\longrightarrow\) Finish.

3D plate#

To create a 3D geometry, after defining all 2D entities, an extrusion is carried out using a mesher:

Finite element analysis#

Finite element formulation#

A 2D small strain formulation under plane stress conditions is used:

****calcul

***mesh plane_stress

**file beam2D.geof

Global problem resolution#

***resolution

**sequence % one loading sequence

*time 1. % time range from 0 to 1

*increment 20 % number of increments. For elastic model use 1

*ratio 0.1 % convergence ratio set to 0.1%

*algorithm p1p2p3 % tangent matrix updated for each iteration

**automatic_time % automatic time stepping, not needed for elastic model

*first_dtime 1e-3 % initial time step size

*divergence 2. 10 % divide time step by 2. if divergence occurs

% (max allowed number of divergence is 10)

*security 1.2 % multiply time step by 1.2 after convergence

% if Delta t <= (sequence time/nbr increments)

Boundary conditions#

There are various methods to apply bending. Below are two examples:

a displacement is applied to the

rightsection as \(U_1^{\tt right}=-\theta y\), where math:theta is the rotation angle. The applied curvature is \(\kappa = \theta/L\). For symmetry, the displacement \(U_1 = 0\) is enforced on theleftsection. To prevent rigid body motion, the displacement \(U_2 = 0\) is imposed on the middle node of theleftsection.***bc **impose_nodal_dof right U1 function -0.5*y; time left U1 0. left_mid U2 0.

The second method involves applying the rotation of the

rightsection as***bc **impose_nodal_dof left U1 0. **linear_rotation right (0. 0.0 1.) (0. 0.5 0.) -20. time; % apply 20 degrees

Imposing rotation of the

rightsection, will induce boundary effects.

Material behavior#

Elasticity: the material behavior definition is given in

elastic.matfile. No integration method is required.***material *file elastic.mat

linear_elasticorgen_evpmodels can be used:% elastic.mat file ***behavior gen_evp % ***behavior linear_elastic **elasticity isotropic % **elasticity isotropic young 2e5 % young 2e5 poisson 0.3 % poisson 0.3 ***return % ***return

Elasto-plasticity: the material behavior definition is given in

plastic.matfile. The \(\theta\)-method is used for the integration of constitutive equations.***material *file plastic.mat *integration theta_method_a 1. 1.e-12 100

% plastic.mat ***behavior gen_evp **elasticity isotropic young 2e5 poisson 0.3 **potential gen_evp ep *criterion mises *flow plasticity *isotropic linear R0 100. H 10000. ***return

Output results#

To output nodal values of stress/strain along the liset left over time.

In addition, one can specify the variables to output in the results database after

**component. To check the available variables, run, for example, Zpreload plastic.mat.

***output

**test results_left.test

*plot

*node_extrapolated

*liset_var left Y sig11 epcum

**component sig11 eto11 eto22 eto33 eel11 eel22 eel33 epcum

****return % end of input file

Post-processing#

The bending moment around z-axis can be computed using the **process static_torsor.

This post-processing computes the torsion moment in terms of the values of nodal

reaction forces on left node set:

****post_processing

***global_post_processing

**nset left

**file node

**process static_torsor

*point (0. 0. 0.)

*file static_torsor.dat % output file name

****return

The bending moment will be stored in the 10th column of the static_torsor.dat file.

Alternatively, we can use **process torque

****post_processing

***global_post_processing

**file node

**nset left

**process torque

*point (0.,0.5)

*direction (0.,0.,1.)

****return

The value of bending moment is stored in the 2nd column of problem.post file

(the 1st is time).

Results#

First, run the finite element problem and the post-processing, and launch Zmaster to visualize the results, using the following commands:

> Zrun bending_plastic

> Zrun -pp bending_plastic

> Zmaster bending_plastic

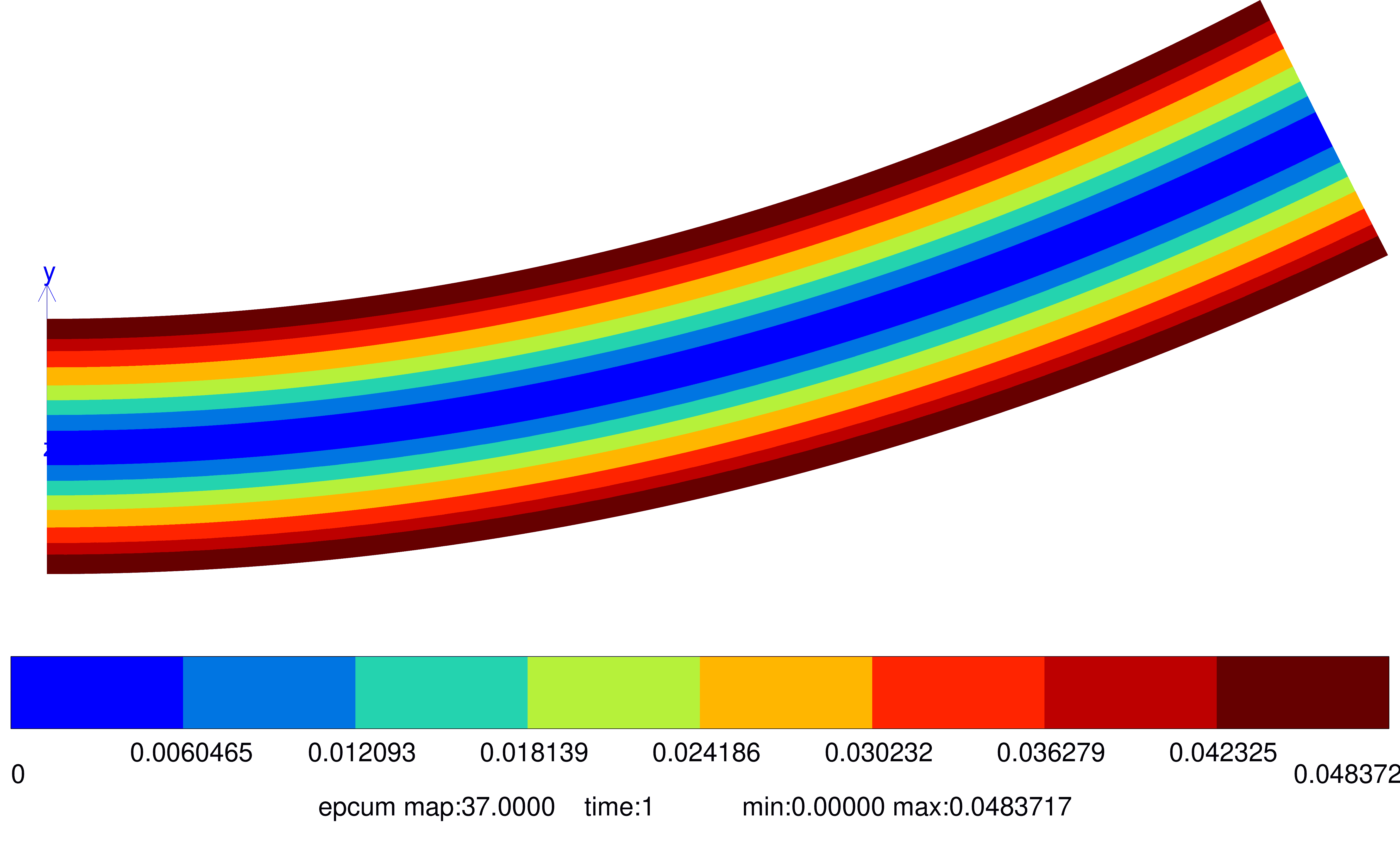

Fig. 64 Cumulative plastic strain#

To plot results along a node set (e.g.

left):Choose the node set

left.Choose the maps to plot in Options (e.g. 20, 25, 30). By default, results from the last map are plotted. When

ALLis typed in Options text field, all maps are taken into account.Click on More, and uncheck Use deformed coordinates.

Export results by specifying the input file name in Curve output, if needed for external processing.

To plot results, click on Draw.

Fig. 65 Illustration of how to plot a variable along a node set for different maps.#

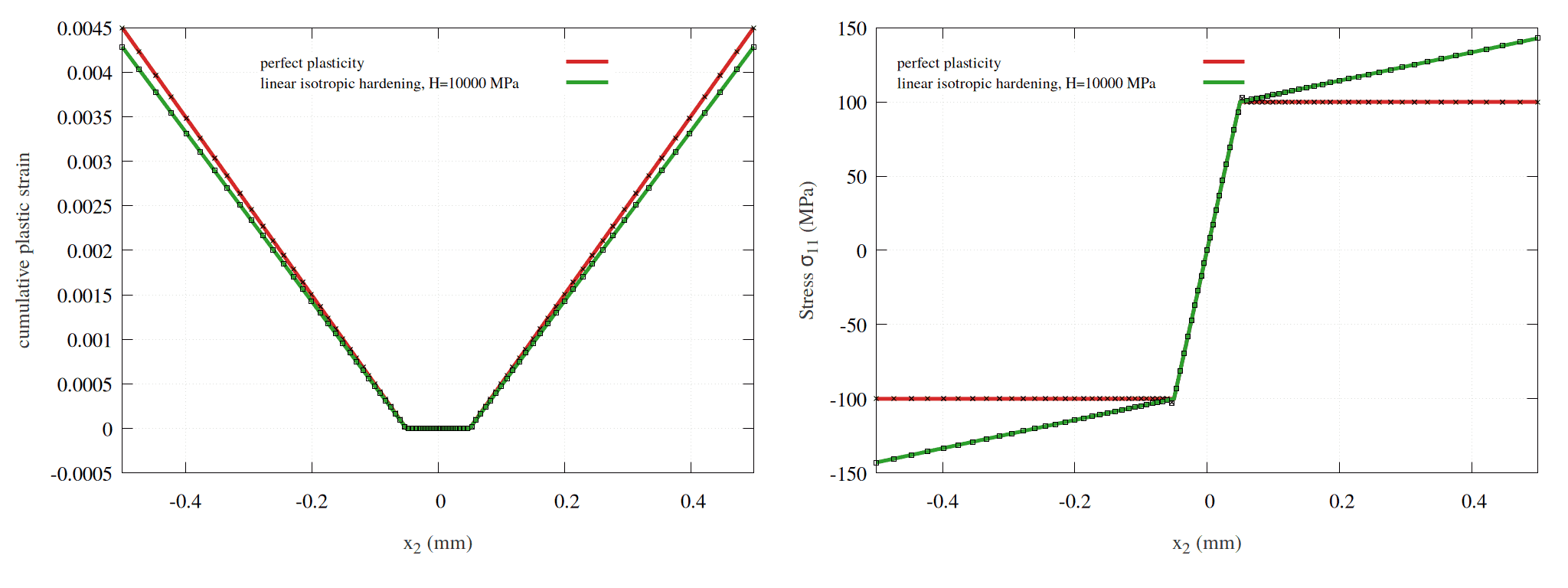

Fig. 66 The stress and cumulative plastic strain along \(x_2\) for \(\kappa = 0.01\). The solid lines represent the analytical solutions, while the marked dots correspond to FEM results. Note that FEM stress/strain values are extrapolated to nodes.#

The bending moment is obtained after running the post-processing. Next, plot the results using Zmaster or your preferred visualization tool. For plotting with Zmaster, refer to the example.

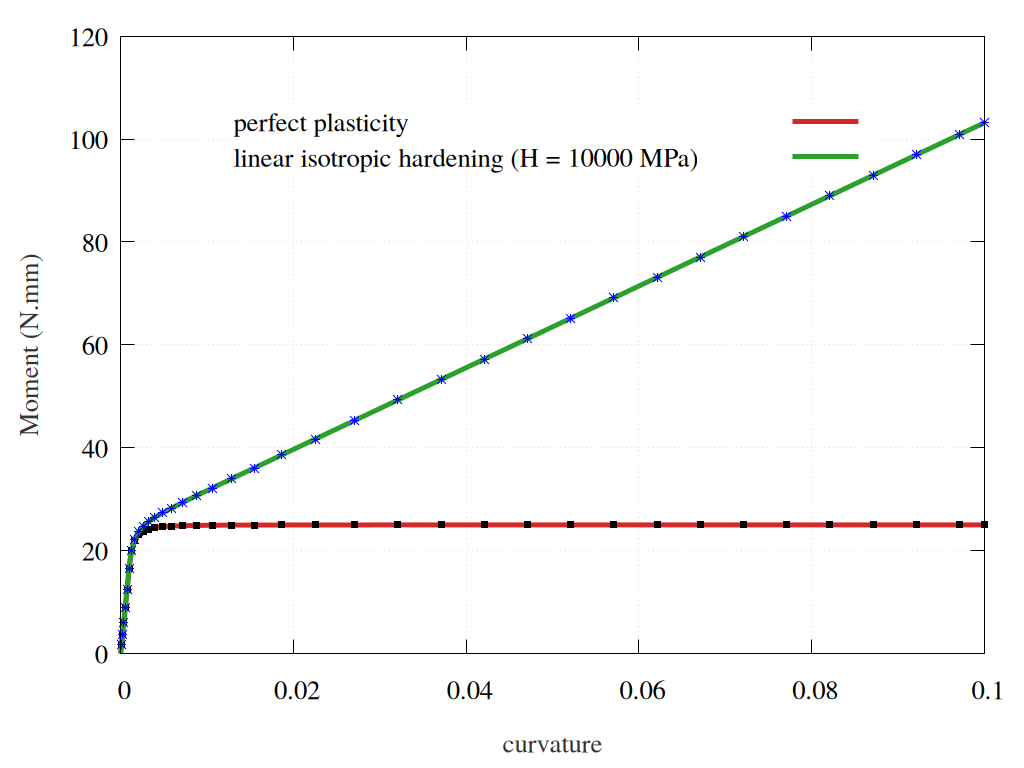

Fig. 67 Bending moment as a function of curvature for a perfect plastic model and a plastic model with isotropic hardening. The solid lines represent the analytical solutions, while the marked dots correspond to FEM results.#

Downloads

Mesh files

Input files

Material files